Here it is, I was going to wait for my Woodcraft covers to come in but did it anyways.

TOOLS NEEDED

1.Metric Sockets 8mm,10mm,12mm,32mm

2.Torque wrench to atleast 98NM

3.Motion Pro Clutch holding tool

4.Ratchets

5.Breaker Bar

5.Digital Caliper

6.Metric allen wrench set

7.Dental pick

Materials

1.New Clutch cover gasket

2.Loctite

3.Yoyodyne slipper clutch

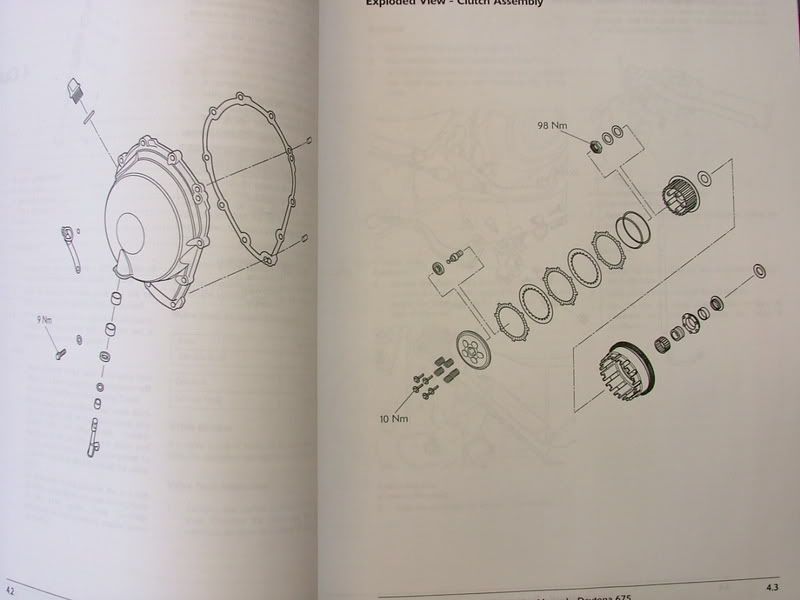

4.675 Service manual if you have it.

5.Brake Cleaner

The install wasn't too bad, with any mechanical skills anyone can install this clutch.

![Image]()

Remove all fairings and put the bike on stands

![Image]()

First step is to slacken clutch engagement line by loosening the two 12mm nuts. Shown Here. Then remove the clutch line from the bracket.

![Image]()

Then remove the cover and place out of the way. You can see some gasket residue left behind, we will get to that later.

![Image]()

Now this is what you will be working with remove the clutch springs with your 10mm socket.

![Image]()

Once all the springs are removed set them aside and remove the pressure plate. I like to set it upside down on some towling just to the left of me so I can then stack the plates on top of it just as they are in the clutch basket.(for easy install later) this is important because you want Xthe plates to go in just as they came out.EXCEPT THE JUDDER SPRINGS AND PLATE THEY GO IN THIRD!

![Image]()

Stacking the plates on the pressure plate

![Image]()

Drive plates behind the pressure plate

![Image]()

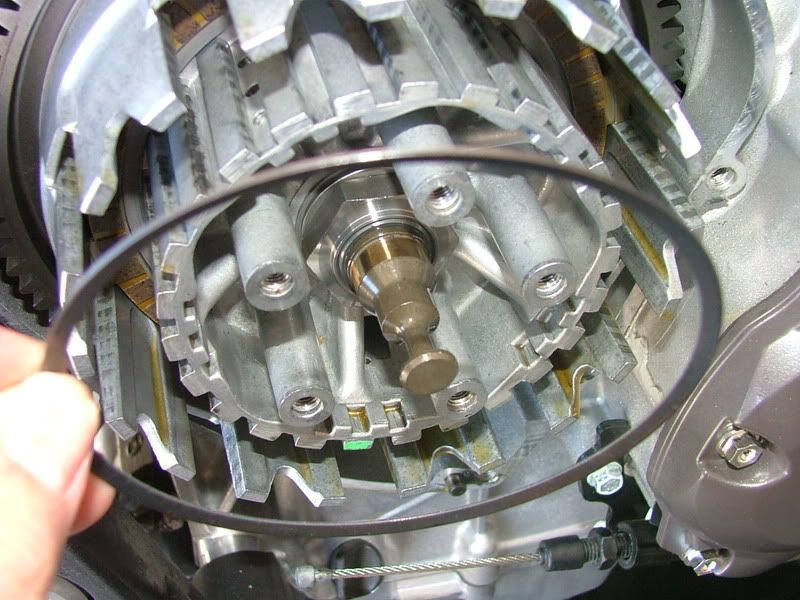

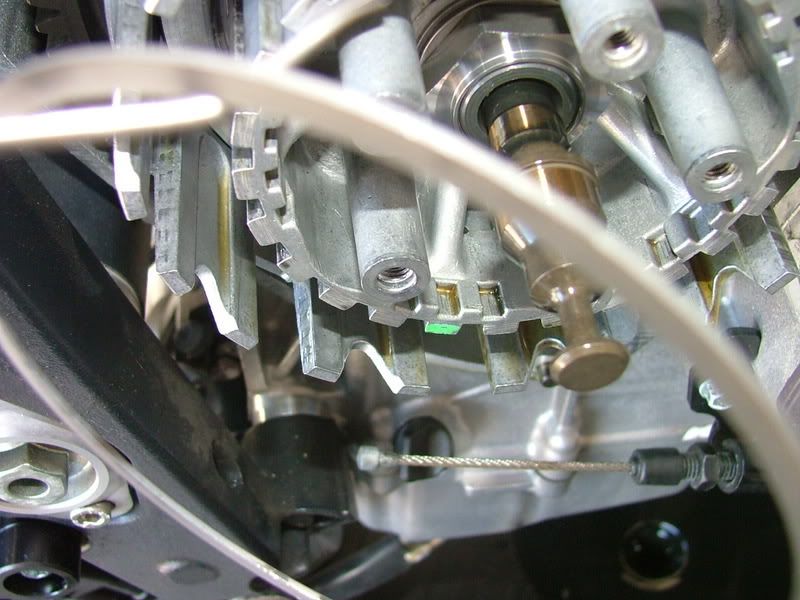

Here is where its nice to have a dental pick, Remove the judder springs remembering exactly the way they came out. The curve faces the clutch cover. THE JUDDER SPRINGS ARE TO BE MOVED TO THE THIRD PLATE IN THE STACK NOT THE FIRST.

![Image]()

Next judder spring, and then theres a smaller friction plate.Thats all of them.

![Image]()

You can remove the clutch actuating pin if you want to inspect it, or just leave it.

Next to remove the clutch drum with the Motion Pro Clutch holding tool. Install the tool inbetween two spleens and hand tighten the knob. HAND TIGHTEN ONLYPlace the end of the tool on the rearset, so the tool can act as a lever so you can remove the nut by yourself using a breaker bar. The nut is torqued to 98NM

![Image]()

Nut Removed you will see this washer telling you what way to reinstall (thanks triumph)

![Image]()

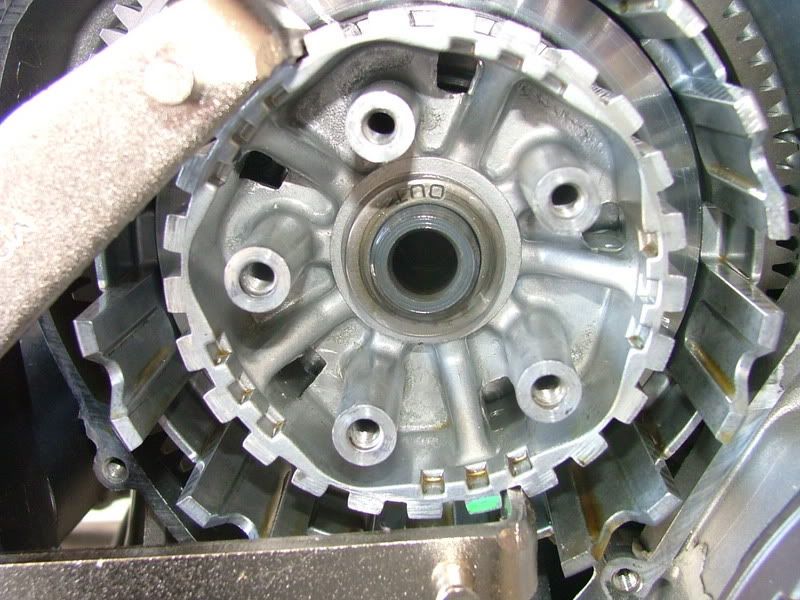

Then you can remove the drum. And now your half way their just time for reinstall.

![Image]()

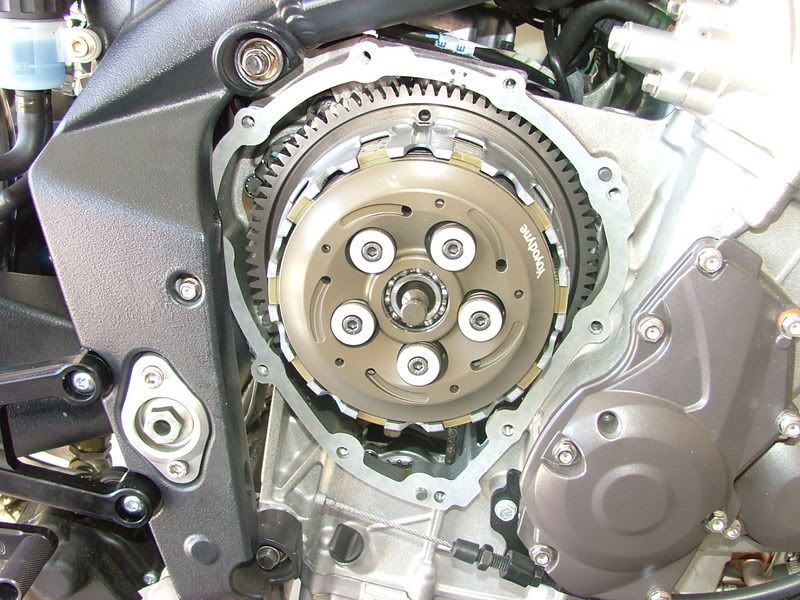

Install the new yoyodyne drum. Install the washers and nut just like you removed them.

![Image]()

Apply the clutch holding tool and get your torque wrench set to 98NM, again put the clutch holding tool on the rearset, but underneath this time.

![Image]()

![Image]()

Then measure the height of the pressure plate to the drum, I came up with 6.58mm with no plates. Then install all the plates(REMEMBER THE JUDDER SPRING PLATE GOES IN THIRD) and measure your stack height.(my battery was dying so it was flashing the reading) with plates installed my stack height came to 7.61 perfect**you want roughly 1 mm of change for the clutch to work properly.Install the springs.

![Image]()

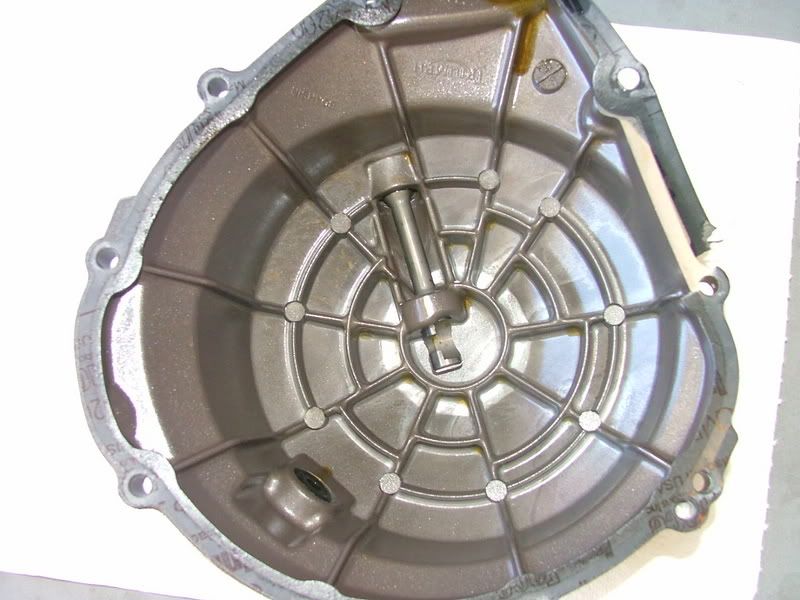

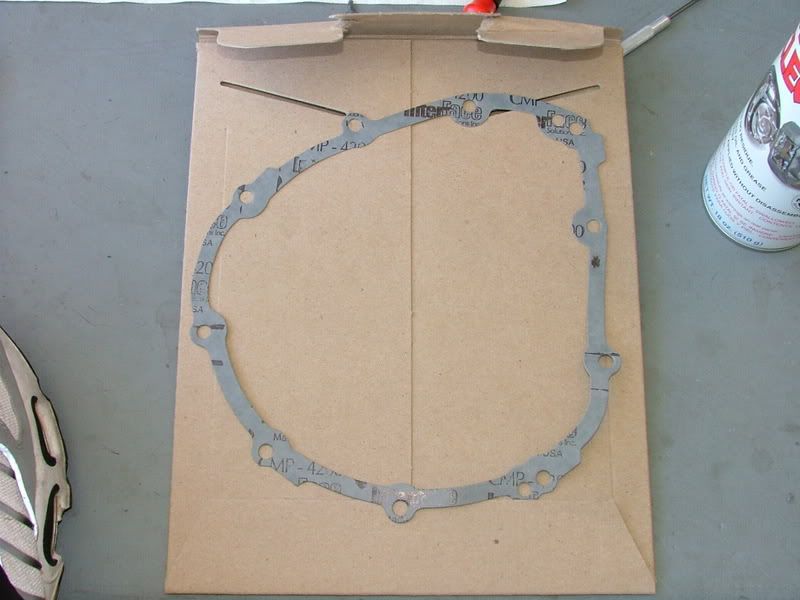

Now to the clutch cover. You want to remove all existing residue from the old gasket. I used some brake cleaner to loosen up the residue then used my fingernail to remove. YOU DO NOT WANT TO MARE THE MATING SURFACE this will create leaks, clean the cover and case.

![Image]()

Clean cover

![Image]()

New gasket, the writing goes on the inside.

![Image]()

![Image]()

The biggest problem I had was getting the clutch line engagement lever back together. Make sure the lever is on the inside of the frame(see pic) and back on the push rod. Then make sure the cover seats on the two locating dowls and install the cover bolts by hand then torque to 9NM.

![Image]()

HOPE THIS HELPS if anyone needs any further help please feel free to instant message. [/img]

[/img]

TOOLS NEEDED

1.Metric Sockets 8mm,10mm,12mm,32mm

2.Torque wrench to atleast 98NM

3.Motion Pro Clutch holding tool

4.Ratchets

5.Breaker Bar

5.Digital Caliper

6.Metric allen wrench set

7.Dental pick

Materials

1.New Clutch cover gasket

2.Loctite

3.Yoyodyne slipper clutch

4.675 Service manual if you have it.

5.Brake Cleaner

The install wasn't too bad, with any mechanical skills anyone can install this clutch.

Remove all fairings and put the bike on stands

First step is to slacken clutch engagement line by loosening the two 12mm nuts. Shown Here. Then remove the clutch line from the bracket.

Then remove the cover and place out of the way. You can see some gasket residue left behind, we will get to that later.

Now this is what you will be working with remove the clutch springs with your 10mm socket.

Once all the springs are removed set them aside and remove the pressure plate. I like to set it upside down on some towling just to the left of me so I can then stack the plates on top of it just as they are in the clutch basket.(for easy install later) this is important because you want Xthe plates to go in just as they came out.EXCEPT THE JUDDER SPRINGS AND PLATE THEY GO IN THIRD!

Stacking the plates on the pressure plate

Drive plates behind the pressure plate

Here is where its nice to have a dental pick, Remove the judder springs remembering exactly the way they came out. The curve faces the clutch cover. THE JUDDER SPRINGS ARE TO BE MOVED TO THE THIRD PLATE IN THE STACK NOT THE FIRST.

Next judder spring, and then theres a smaller friction plate.Thats all of them.

You can remove the clutch actuating pin if you want to inspect it, or just leave it.

Next to remove the clutch drum with the Motion Pro Clutch holding tool. Install the tool inbetween two spleens and hand tighten the knob. HAND TIGHTEN ONLYPlace the end of the tool on the rearset, so the tool can act as a lever so you can remove the nut by yourself using a breaker bar. The nut is torqued to 98NM

Nut Removed you will see this washer telling you what way to reinstall (thanks triumph)

Then you can remove the drum. And now your half way their just time for reinstall.

Install the new yoyodyne drum. Install the washers and nut just like you removed them.

Apply the clutch holding tool and get your torque wrench set to 98NM, again put the clutch holding tool on the rearset, but underneath this time.

Then measure the height of the pressure plate to the drum, I came up with 6.58mm with no plates. Then install all the plates(REMEMBER THE JUDDER SPRING PLATE GOES IN THIRD) and measure your stack height.(my battery was dying so it was flashing the reading) with plates installed my stack height came to 7.61 perfect**you want roughly 1 mm of change for the clutch to work properly.Install the springs.

Now to the clutch cover. You want to remove all existing residue from the old gasket. I used some brake cleaner to loosen up the residue then used my fingernail to remove. YOU DO NOT WANT TO MARE THE MATING SURFACE this will create leaks, clean the cover and case.

Clean cover

New gasket, the writing goes on the inside.

The biggest problem I had was getting the clutch line engagement lever back together. Make sure the lever is on the inside of the frame(see pic) and back on the push rod. Then make sure the cover seats on the two locating dowls and install the cover bolts by hand then torque to 9NM.

HOPE THIS HELPS if anyone needs any further help please feel free to instant message.